Renovation of the shipping warehouse in ETI Izlake

In the first half of 2022 we completed the renovation and expansion of the shipping warehouse in Izlake. By doing so we gained approximately 650 square meters of additional storage space and almost 5,000 additional storage locations (4,647 shelf and 233 pallet storage locations).

| Sebastjan Lazar |

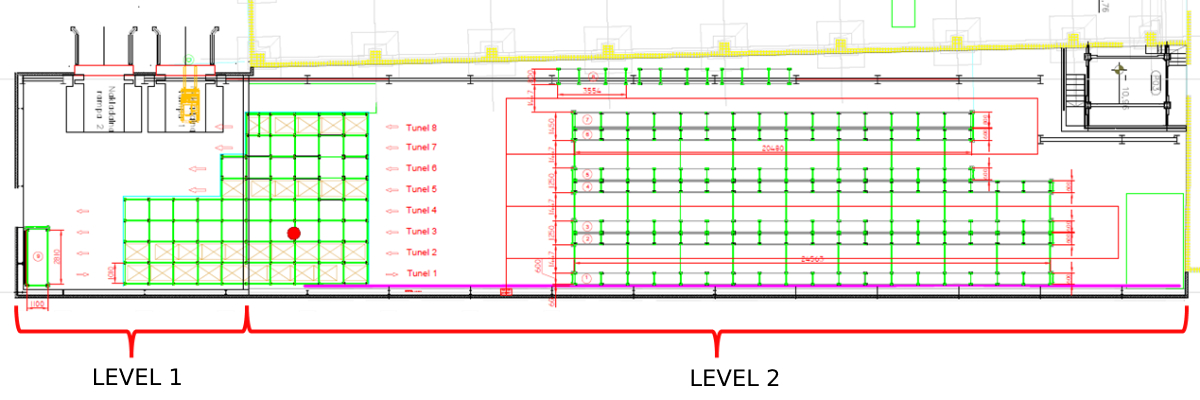

This new part of the warehouse is mainly intended for the storage and manipulation of products that are not manufactured in the parent company ETI, but are obtained from internal or external suppliers. Facility is designed in two levels, between which there is a height difference of about one meter. This height is overcome mainly with the help of eight tunnels of the flow and push pallet system (manipulations within the mentioned system are carried out with the help of the new three-wheeled forklift EFG 220, which allows lifting up to 6.5 meters).

Layout of the new part of warehouse

The first level of the warehouse is mainly intended for loading onto vehicles or unloading from them, while the second level of the warehouse is mainly intended for commissioning. The part of the warehouse, which is intended for order picking from or to the shelf location, has four aisles, where each of these aisles represents its own order picking zone (zone codes are G1, G2, G3 and G4).

The basic idea of shelf storage or carrying out manipulations is that there is only one product code at one shelf location, which subsequently means significantly greater possibilities for further improvement of logistics accuracy (fewer logistics complaints). When organizing work in the new part of the warehouse, the FIFO methodology is also used, which means that the product that is received first is also released first (taking into account the preset FIFO rules). Shelf picking is carried out in the new part of the warehouse with the help of three completely new EKS 310s vertical forklifts.

Due to the great emphasis on the safety of all employees, all three mentioned forklifts have a built-in system to prevent collisions with other forklifts or people. In the desire for a high degree of automation and a faster flow of products from and to the shelf storage location, we have designed the work process in such a way that each of the three mentioned forklifts has an implemented navigation system, which can increase the work flow in the warehouse by up to 25%.

Commissioning with the help of a forklift, which has the option of a navigation system, in practice means that the forklift, with the help of the information system, the logistics interface and the inductive loop in each of the corridors, brings the employee to the shelf location at which the receipt or issue must be carried out (including by automatic positioning to the desired shelf location, regardless of its height). As part of the renovation of the shipping warehouse, we also installed two loading ramps, which undoubtedly makes our work easier and speeds up the process of operation of the mentioned warehouse from the point of view of unloading or loading onto vehicles.