New generation of tools for perforating melting elements

Perforation of the melting element is one of the most important stages in the manufacture of fuses, which significantly affects the performance of the product. Customers' demands for quality and quantity have increased significantly in the last years, so it was time for a renewal of the tools and machines (presses), on which perforation is made.

| Bojan Urankar Constructor |

perforate |

pierce and make a hole or holes in. |

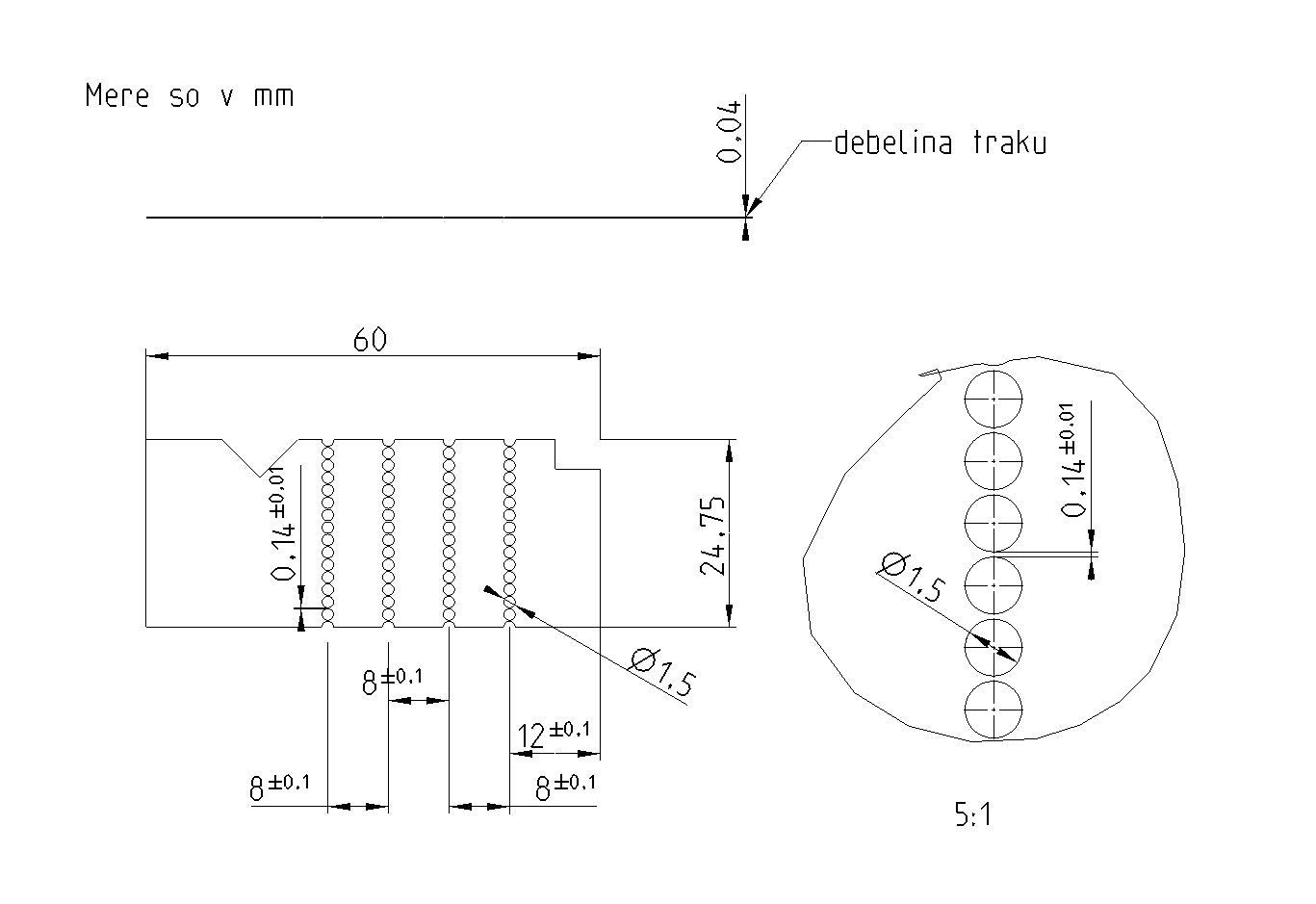

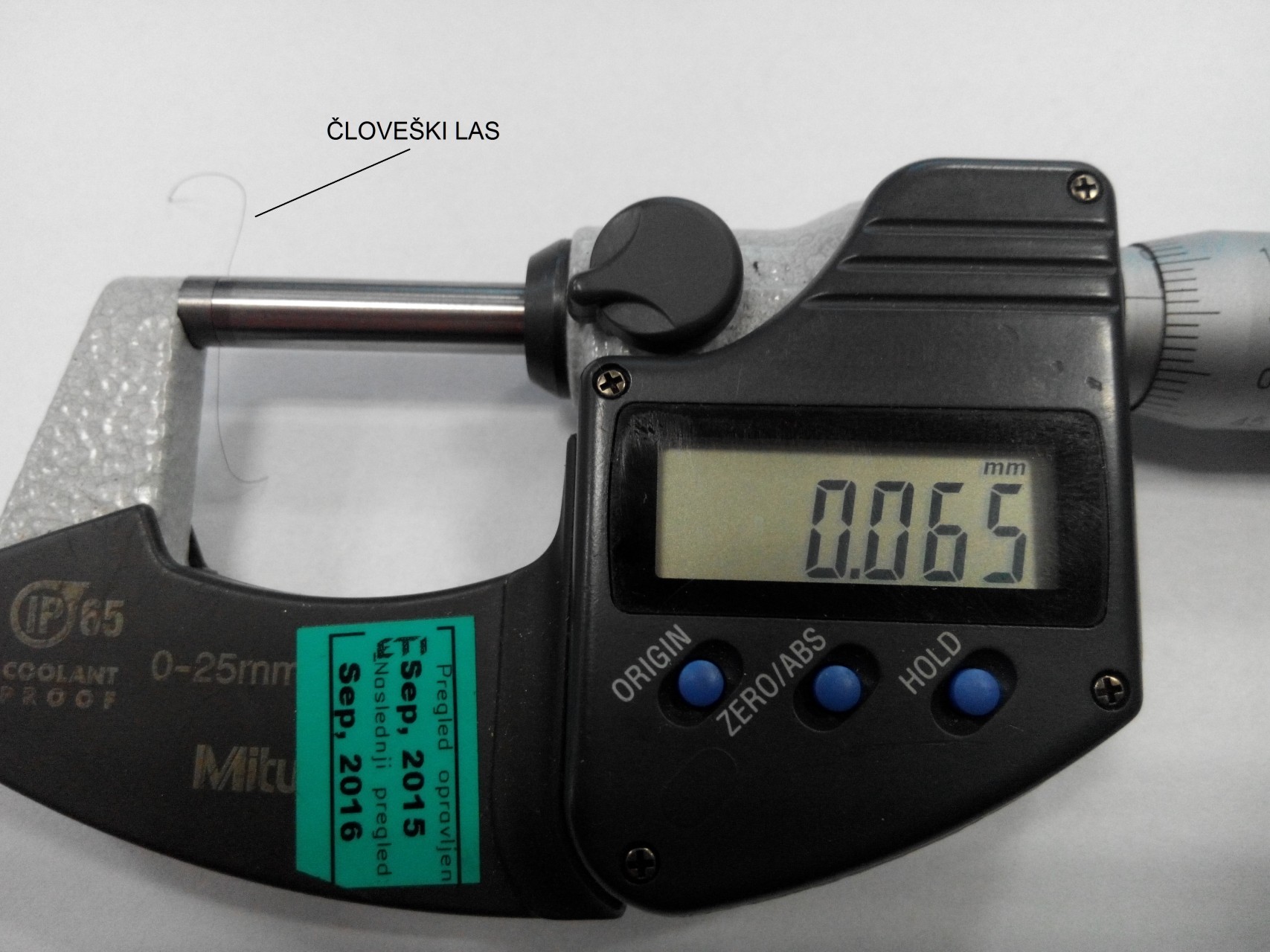

Melting element with perforation of round openings: openings' diameter and thickness compared to that of a human hair

|  |

Advantages of the new generation of tools:

- higher quality of perforation,

- improved efficiency and reliability,

- increased flexibility in changing product type,

- improved working conditions,

- increased tool life, simplified maintenance,

- reduced maintenance and operating costs.

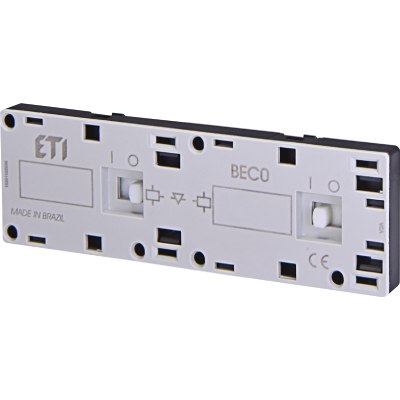

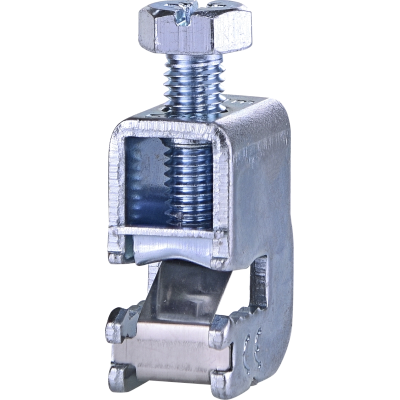

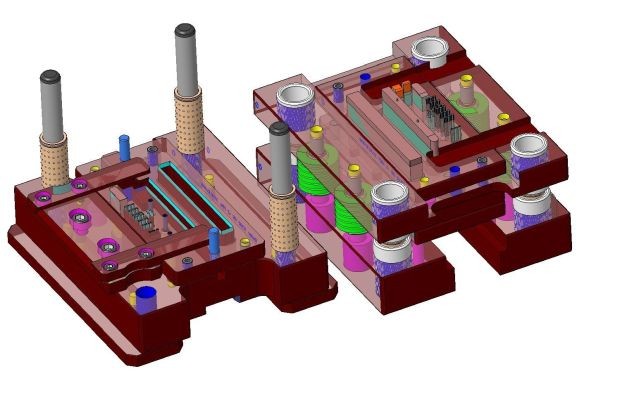

An example of one of the old tools for perforation:

DEVELOPMENT OF NEW TOOLS

In parallel with the development of new tools, we also replaced the existing presses to increase both the quality and quantity of perforations. The new presses allow up to 600 rpm.

With the new presses we are now able to produce up to 6 times the output of the old ones. Not to mention the obvious reduction of noise and almost zero consumption of compressed air.

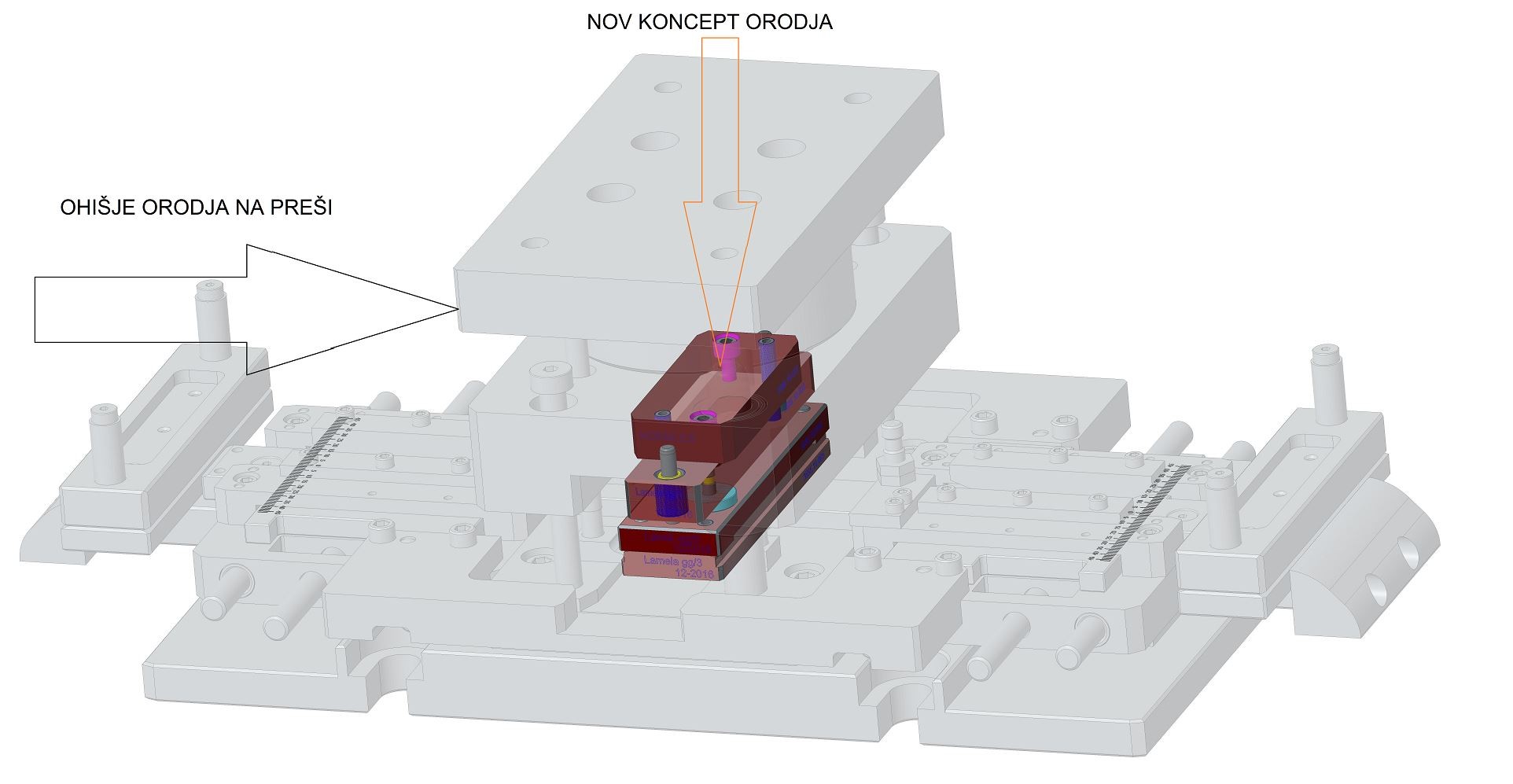

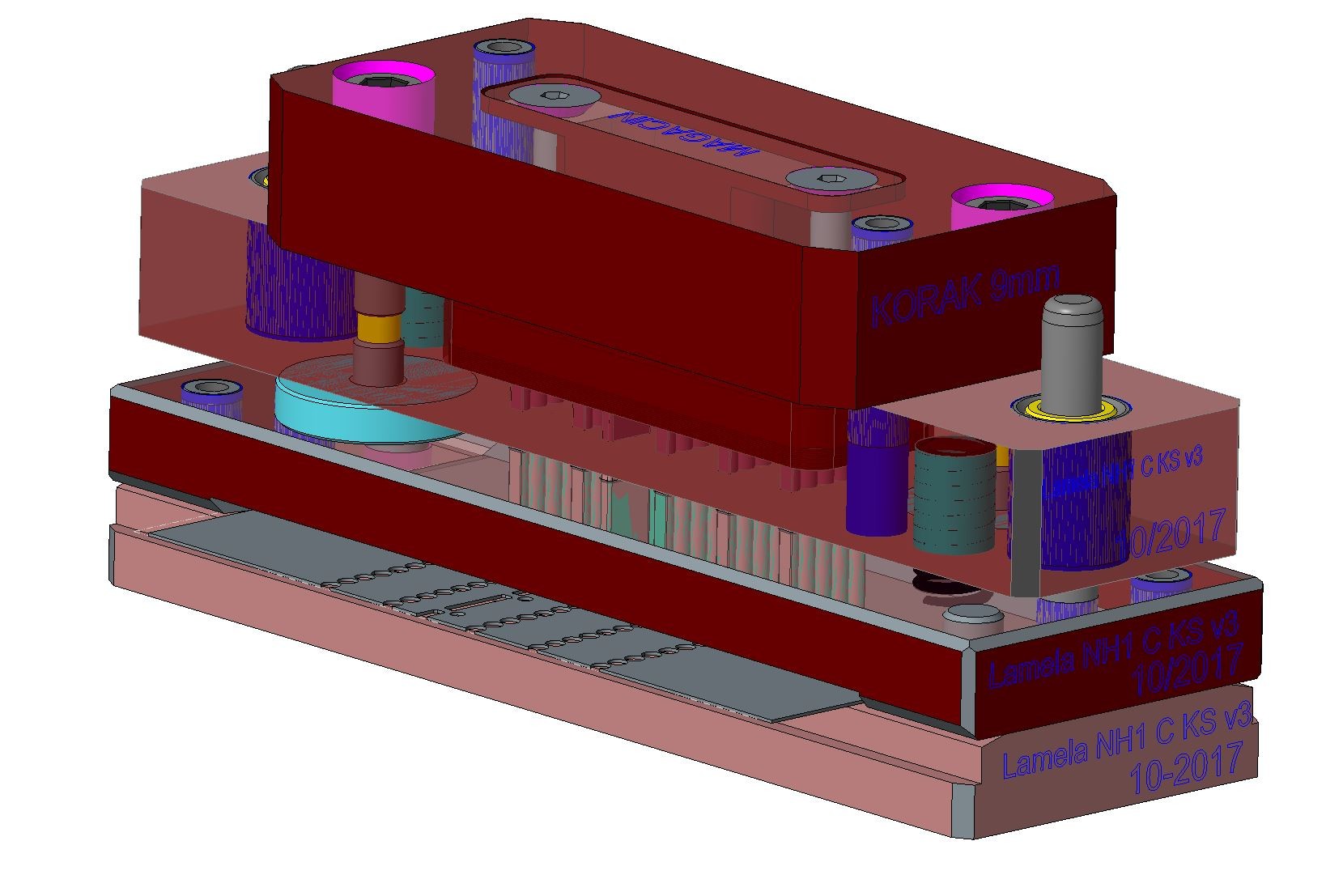

We have developed a new and innovative concept of the entire tool, where the tool support plates and belt guide rails remain clamped in the machine. So when we are changing the perforation matrix, only the tool core (cutting parts where the sheet metal is perforated) is replaced.

|  |

With the selection of new cutting materials in the tool and with the additional application of a hard metal coating, we extended the service life of the cutting parts from the current 100,000 strokes to the achieved 800,000 without maintenance or sharpening of the tool. We have simplified some tools so that minor maintenance work on the tools can be done in the production unit itself (replacement of round standard cutting parts).

The new generation of perforation tools is the result of constructive cooperation and exchange of experience between development, production, technology (ETI) and the ETI PROPLAST tool shop. The test for cutting shape openings was performed on a CUT 1000 Water wire erosion machine at +GF+ in Switzerland. The results were above expectations both in terms of manufacturing accuracy and surface quality.

The tool was then monitored during operation and analyzed both in the tool shop and in production, up to more than 2,000,000 produced cutouts. We found that the wear of the blades is significantly reduced compared the parts, created with wire erosion. By using a new technology of manufacturing perforation tools, we were able to achieve higher quality of perforation and improved efficiency and reliability of the tools over time.

Currently, new improvements and innovations are being considered to make work easier and increase productivity, safety at work and further improve the quality of the melting elements.